If you’re looking for a way to reduce costs in your business and think you have exhausted all avenues then, maybe your packaging holds the key to further reductions.

Packaging can play a vital role in giving you a competitive edge, it’s got the potential to help uncover savings within your business and boost your operational efficiency.

Cost savings on packaging are typically reviewed in isolation – on an item for item basis. For example, a tender process where suppliers bid to supply ‘like for like’ products based on current usage from an incumbent supplier. This is a great way to shave a few pence off each individual item, but what happens when you need to reduce costs further. How much juice can you squeeze from the packaging lemon?

Not all the costs in your packaging operation are visible to the naked eye. In fact, as much as 90% of them are hidden.

With packaging there is always a bigger picture, and it typically leads to bigger cost savings. Think about switching your focus to the packaging itself. Identifying key areas for improvement could take you to a solution that delivers larger savings long term. This can include reduced damages, improved palletisation, reduced transport costs or maybe it takes less time to pack and speeds-up throughput.

A packaging review may also arrive at a solution that uses less material – reducing the amounts of packaging that you actually use. This will contribute to reducing costs and ticking the corporate social responsibility boxes.

Here are 5 key areas where packaging can help to uncover possible cost reductions:

Storage Costs

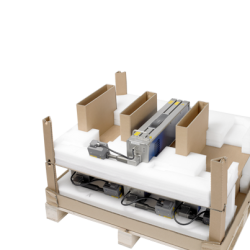

Are you storing bulky packaging onsite? If so, it’s tying up valuable floor space. Is there an opportunity to switch to a less bulky solution, or one that takes up less space in storage? Or perhaps the stock can be stored by your supplier and delivered as and when needed. There could be opportunities for savings on insurance and rent.

Transport Costs

Packaging can deliver more than just product protection. Get it right, and it could offer significant savings in transportation costs and an increased payload. A thoughtfully tailored pack can make an entire logistics chain run more efficiently, helping you to increase your payload, cut down on vehicle runs and reduce your carbon footprint.

Are products being packed to deliver the best possible cubage for your product? Does the packaging significantly add to the shipping weight? Do packs require void fill that could be minimised or avoided? Can packs be standardised to fit multiple products? Is the pallet surface area being maximised?

Remember, the key to all of this is remembering that protection is still paramount – there is no point in reducing your transport costs if your damage and returns are going to increase. If in doubt, a packaging professional can advise you on the best way to proceed for your products.

Damages and Returns Costs

Are you aware of the financial costs of damages and returns in the business? There’s the cost of the write-off of the original product (if damaged), the cost of the replacement, double transportation costs to redeliver (triple if you offer a returns service). Not forgetting the labour charges to pick and pack the order again and administration costs to process the return.

Damages and returns can be a significant cost for industries and it’s not just a financial cost. A reputation as a reliable manufacturer can also be tainted.

When you are able to get a handle on the true cost of returns, you can then confidently investigate a solution that delivers improved protection based on commercial results. It may cost 10% more to protect the goods, but it could be reducing your total damage and returns costs by 80%.

The right combination of materials is crucial in ensuring excellent product protection while minimising your shipping costs. There’s a wide range of non-hazardous, sustainable packaging materials available on the market. Consider speaking with a packaging expert about choosing the best solutions for your products and requirements.

Productivity Costs

Packing goods can be a labour intensive task. The longer it takes you to pack the product, the slower you are getting goods out of the door – and the more it costs you in £s.

Investigating a quicker way to pack goods by using alternative pack designs and easy erect packs could help to reduce your costs and speed up your productivity.

Customer Experience

Customer experience has fast become king in the retail world and it shouldn’t be any different with B2B.

It is all about first impressions, conveying the value of the goods and getting the order there complete and in full working order. How easy it is to unpack the product and recycle the packaging? Success for any business is about customer retention and repeat orders – it is vital that products are dependable and stand out.

Heavy industrial products can be packed to ensure that it can be safely handled on receipt – hand holes, lockable castors, packaging ‘doors’ that convert to ramps, branded envelopes to hold instructions to ensure they don’t get disposed of with the pack…the possibilities are endless.

Macfarlane Packaging can help you ensure your products are cost effectively protected throughout the entire supply chain. Get in touch: https://macfarlanemanufacturing.com/contact-us/